By Peter Abraham — Like many physical objects in our lives, most of the bikes we ride are made in China. In 2021, 76 million bicycles were manufactured there. Even many Italian brands that project the aura of artisanal, handcrafted bikes are mostly made there.

American bike manufacturing took off, along with the popularity of the bicycle, in the late 1890s. Bicycles subsequently went through boom and bust cycles in the 1930s and the 1970s. Bike brands started to look for a cheaper manufacturing solution outside of the United States after that, and Asia is where they ended up.

Chinese manufacturing for export took off in the ’80s and ’90s as the country opened up to the idea of business. Given the massive size of the Chinese manufacturing ecosystem, it’s amazing that the first business license in that country was not issued until 1979. The speed of growth in every Chinese industry has been extraordinary. One can understand how bike building got exported there: bikes are fairly low tech products that require lots of labor to build. So a manufacturing system with millions of workers who are paid a fraction of Western workers sounds appealing.

So in the span of 30 years, bike manufacturing took hold in China (and Taiwan as well) and became a huge industry. And even though performance bicycles mostly switched from steel & aluminum frames to carbon fiber, the Chinese system adjusted with it. Higher tech manufacturing was attainable there. Indeed at the same time the bicycle manufacturing industry was growing in China, tech products were exploding as well. Apple is responsible for about 5 million jobs in China, mostly tied to iPhone production.

The number of bikes made locally in various countries around the world has dwindled as the Chinese manufacturing system took hold. And so did the expertise and craftsmanship required to make a bike. Those skills largely disappeared as the jobs were exported to the Far East. As I started working increasingly for bicycle businesses over the last six years, I wondered if there was a downside to all of this Asian manufacturing. I went back and forth between, “Hey, we live in a global economy, this is how things get made.” and “Can we ever get high skilled manufacturing jobs back here to the US?”

Starting in 2019 I spent a lot of time thinking about these issues, and in 2021 I started visiting bike factories during my travels to different places. While Asian expertise has gotten very good with respect to making high performance bicycles, there are a bunch of challenges associated with making bikes that far from home:

- Slower production process in general. Upcoming orders for a bike must be placed well in advance, years even, and demand forecasting is a full time position at most larger brands.

- As the pandemic showed, producing a product in another country exposes any kind of business to a whole bunch of variables outside of their control. For bike production, there were many supply chain disruptions due to COVID issues, and then a resulting whipsaw effect that had product finally arriving in warehouses just as demand was falling off.

- Chinese production of products destined for sale in Europe or the US requires packing bikes into boxes and shipping them across the ocean inside of a freighter. This is not great environmentally and opens up even more potential supply chain issues.

- In the U.S., there are trade tariffs of up to 25% on lots of Chinese-made bikes and parts. While some of these were relaxed in 2022 (until the end of 2023) thanks to the hard work of the People for Bikes trade group, there are still many components and bikes subject to additional fees.

- It’s better for the customer when they are in closer proximity to where the bikes are being made. The current distance between cyclists — whether in Australia, Europe or the United States — and the places where their bikes are built results in products that are less responsive to customer tastes and changes. Say a brand learns that a certain size or color or component build is selling better than expected. It’s just harder for them to respond to that given all of the in-between steps that happen with Asian production.

While it sounds good to just “make bikes locally” there are a lot of things that must change for that to happen at scale. Importantly, most bikes are currently made with a very labor intensive process that perfectly takes advantage of the much lower labor costs in Asia. Whether that’s welding aluminum tubes or painstakingly cutting hundreds of pieces of carbon fiber fabric for a single pre-preg carbon frame, the $3–5/hour that Chinese workers are paid makes these processes far, far less expensive than manufacturing elsewhere. So a less labor intensive, more automated process will help move bike manufacturing back onshore. These technologies, like 3D printing and resin transfer molding (being used by Time Bicycles) , are improving all the time and are on the way to becoming inexpensive enough for mass production. Change is coming and people are working to develop these (and other) technologies. (Full disclosure: I’m part of a 3D printed bike frame technology startup)

In this post I am talking about the frame of the bike, which is composed of lots of components (drivetrain, seat, wheels, tires, handlebars, etc.) that are mostly made in Asia. So even with a frame that is made domestically, those parts have to be shipped in from Asia to wherever the bike is being assembled.

While there are many small and medium size bike brands making bikes locally, here are three factories that I visited in order to learn more about what’s involved:

Festka Bicycles in Prague, Czech Republic

Our daughter Sadie lives in Prague, so when we started visiting her there in 2021, I’d call up the people at Festka and go for a visit. Their factory is tucked away in the upscale Vinohrady neighborhood of the city. If you know Festka, you are aware that their point of differentiation is the beautiful way their bikes are painted. They’ve had a creative director on board at the company from the start, and it’s clear there’s a designer’s point of view behind the look of each bike.

While their bikes are not technically too sophisticated, using a wrapped carbon assembly process and round tubes, the bikes are entirely built in and around Prague, in the Czech Republic. This includes the tube manufacturing, the assembly and the painting. And Festka has fans all over the world: on my last visit to the factory, I saw bikes being shipped to the Middle East, to Taiwan and to Miami, Florida. The brand’s founder and owner, Michael Moureček told me, “An ugly bike costs just as much to build as a beautiful bike, so why not make a bike people are excited to ride?” Amen.

Brompton Bicycles in London, UK

I met Brompton CEO Will Butler-Adams at the Bicycle Leadership Conference here in California. He generously said, “Hey, Peter, if you’re ever in London, then stop by for a visit.” Well, I was in England in late September, so my colleagues Henry Furniss, John Hale and I rode our bikes across the city for a tour.

Brompton makes unique folding bikes that are ideal for multi-modal transportation: ride it from home to the train station, then fold it up to sit next to you on the train, the unfold it to ride to your final destination. Bromptons are functional, disctinctive and beautifully engineered. The first thing you notice walking up to their factory in the Greenford neighborhood is how big the building is. It’s a much bigger and more professional operation than we expected. Will greeted us at the front door and spent two hours showing us around the plant. They make 500 bikes per day in this one building, and their bikes are shipped all over the world.

The assembly line was more technically sophisticated than I expected. For example, every torque wrench is wired into a database, you could go back years later to understand who’d worked on a specific bike and to what torque setting a bolt was inserted. Will shared both his entire facility and his ideas with us. I loved that the brand’s mission statement was printed in large letters up on the wall of the main room: “We create urban freedom for happier lives.”

Overall, we were really impressed with their product and leadership.

Allied Cycle Works in Bentonville, Arkansas

I travel to Bentonville, the home of Walmart, a couple times a year for riding or work, or both. I love the transformation of that region to a bicycle led culture. (I’ve written a blog post about why the region is exploding, if you want to learn more). One of the important trends there is the number of bike-related businesses that are moving to the region. I believe this area has the potential to be a “Silicon Valley for bikes,” with lots of businesses in close proximity. One of those is Allied, which is owned by Tom and Steuart Walton (grandsons of Walmart founder Sam Walton) via their Runway Group holding company.

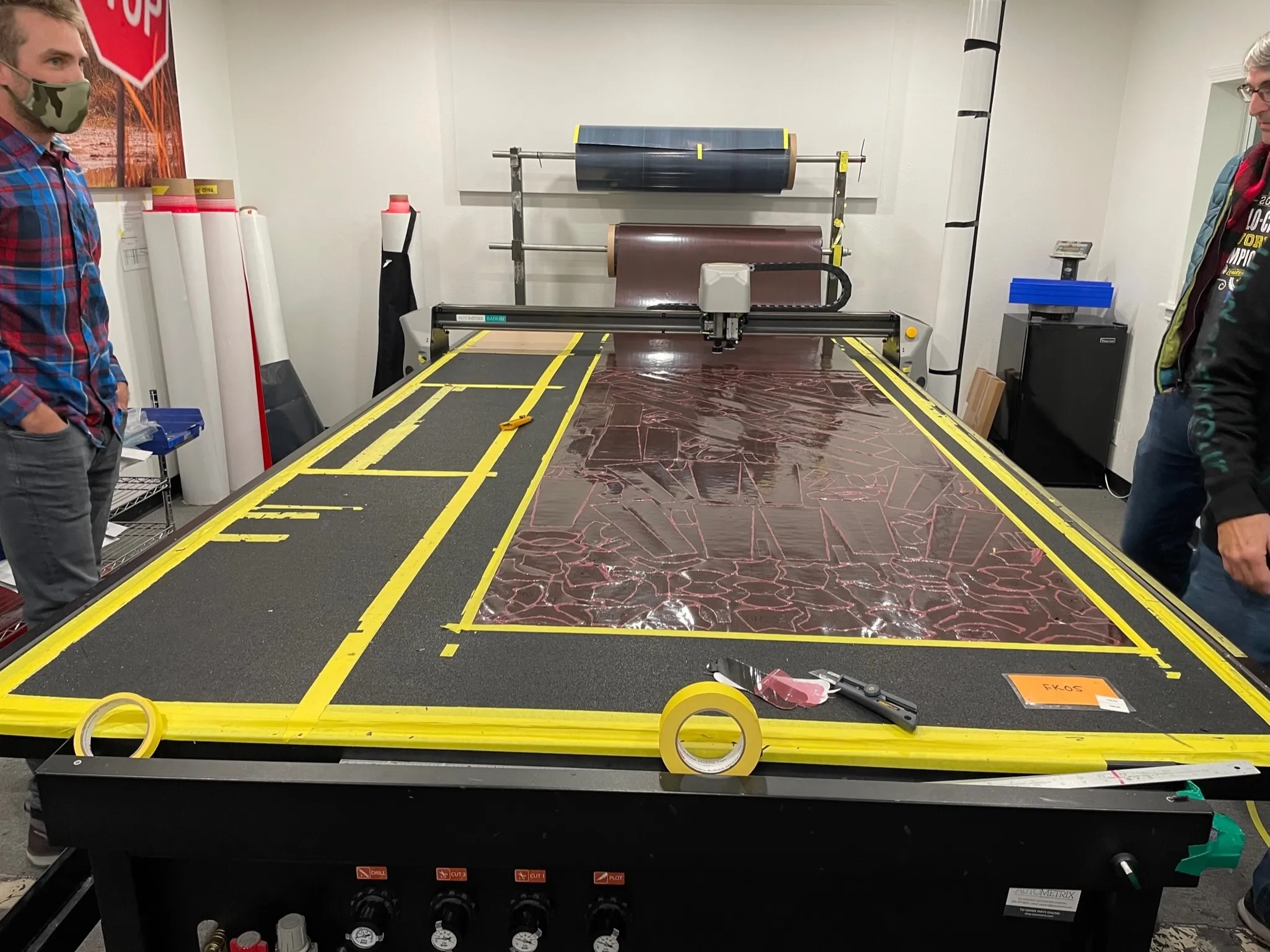

I took a tour of Allied when I was in town for the UCI World Cyclocross Championships in 2022. Like Festka and Brompton, Allied was tremendously open about how they build bikes. Sales Manager Will Stoffel took a couple hours to show us the entire process.

Allied produces about 1,000 frames per year in this building, and they sell through a mix of direct-to-consumer (DTC) and wholesale (bike shops) channels. While their bikes are fairly traditional in construction (using the prepreg carbon fiber process), I appreciate that they have actually brought carbon fiber bike manufacturing back on shore to the United States. There are not many brands, if any, that produce this many carbon fiber bikes here.

Taking a tour here reminded me how many steps are required to build a good bike. It’s a time-consuming process filled with hundreds of separate steps. Given their hands on process, labor costs are a continuous challenge for Allied, particularly with the number of other employers in Northwest Arkansas. But I found the visit really inspiring.

Overall, I believe bike manufacturing will begin to move back to countries closer to where the bikes are sold. Not all countries will do this, but expect to see more bike factories in Europe and North America. The brands that succeed with this strategy will figure out how to turn this manufacturing shift into positive changes for their customers. After all, if a significant business shift like this does not benefit the customer in some way, what’s the point of doing it?