When I worked at A Bicycle Odyssey, in Sausalito, California back in the mid-to-late-1990s, building bikes out of carbon fiber was still a relatively new phenomenon; most of the bikes we sold were custom-built steel, aluminium, or titanium. Some of us were wary of carbon fiber because it was perceived as being brittle and unrepairable. Over time, of course, engineers and builders at bicycle manufacturers become more experienced with the material, which has now effectively replaced all of the metals previously used on high-end bicycles.

Even so, the fact remained that when carbon fiber fails, it tends to fail catastrophically. As such, even small dings must be investigated to make sure there are no cracks or other underlying damage which could cause a total frame failure. Until recently, damaged frames were generally written off as a total loss that needed to be replaced. However, in the past few years more companies are opening with their primary business being the repair of carbon fiber bicycle frames. One such company is East Bench Composites, based in Ogden, Utah, which was founded in late 2020 by Jordan Weininger. Cycling West recently sat down with Jordan to learn more about his business.

SLS: Jordan, tell us a little bit about yourself; your background and education, and how you came to the sport of cycling.

JW: My first real introduction to the cycling world was in college at Clemson University, when my roommates and I bombed through the woods of upstate South Carolina on Gary Fisher hardtails, with zero knowledge of the sport or cycling culture. We were just having fun (in those few moments we were not going OTB). Eventually, we joined the university’s club cycling team, and I also got a job at Clemson University’s outdoor program managing their bike shop, and leading outdoor trips for other students. Soon I was the kid reading more pinkbike tech articles than anything related to school, but still interested in it from a mechanical engineering perspective.

Professionally, my first introduction to the cycling industry was a job with SR-56; the product development arm for Crankbrothers, Fizik, and Selle Royal, which at the time was based in Ogden, Utah.

SLS: How did you start to work with carbon fiber and other composite materials?

JW: At SR-56, I was a Junior engineer on the Crankbrothers Synthesis carbon wheel line, and I was learning, but just too slowly. Eventually I moved on to a position in the Advanced Composites Office on Hill Air Force Base. With the resources of the aerospace/defense industry, I was able to learn the skills required to inspect damage, design structural repairs, and carry out composite repairs for structural components on various airframes.

SLS: What made you decide to apply your engineering skills and knowledge to bicycles, rather than continuing to work with the Air Force on planes?

JW: Mainly it was for environmental reasons. Once I learned how taxing carbon development is on the environment, I just couldn’t stay a part of that system. All the red tape involved in aerospace tested my patience, and my values of conservation and efficiency just didn’t align with the Air Force. I always planned to take what I learned back to the outdoor industry eventually, in one form or another.

Meanwhile, I noticed other major cycling communities have a local carbon repair shop: California has Calfee, Portland has Ruckus, and Denver has Broken Carbon. Utah has a HUGE cycling community that I am proud to be a part of. But before EBC, there was no professional local carbon repair company. Which is crazy to me!

I realized that based on my background, I was in a unique position to offer the service I wanted to see in our community. With the help of my friend Clay Ahlf, a long time Enve employee, we got to work starting what has become EBC.

SLS: How is what East Bench Composites does different from other carbon fiber repair companies, such as Ruckus Composites or Calfee?

JW: First of all, I have a ton of respect for Calfee and Ruckus; Their repairs look great, and they have been doing this for a while.

While there are many ways to fix a bike, most other carbon repair companies will use the same layup or a wrap for the similar repairs; (i.e., all mountain bike seat stays get the same layup). This neglects considerations for geometry, and can create large stress concentrations at or near the repair area. For example, a 1” diameter downtube and a 3” diameter downtube require quite different layups to achieve the same stiffness.

By contrast, our repairs use the Scarf repair method taught in the aerospace industry. This method removes the minimal amount of original material necessary, and orients the fibers of each layer to match the original design. This is the best way to replicate the strength and stiffness that the bike manufacturer intended. At East Bench Composites, each bike has a specific layup because the bike was designed to fulfill a specific purpose.

Additionally, we only use prepreg carbon fiber with a toughened epoxy resin system. This means the carbon and epoxy are perfectly mixed from the factory at the correct ratio. Some companies use wet layups for their repairs, and while this requires less specialized equipment and is a cheaper option, it is more wasteful when it comes to processing materials, and the resulting material is often much weaker than a prepreg composite since it is very difficult to get a perfect carbon/resin ratio every time.

SLS: Can you walk us through your process of doing a repair?

JW: The main steps involved in a repair are:

- Ultrasound inspection to determine the extent of the damage (unless the member is clearly broken all the way through). Sometimes damage is just superficial and no carbon repair is necessary.

After identifying the location of the damage, the frame is undergoes an ultrasound inspection to determine the extent of the damage. - Sanding away the damaged plies: Carefully sand away the damaged plies of carbon and read the layup. This means determining exactly how many plies, their order, and fiber orientation with a magnifying glass. It takes practice, but when we are doing 4 bikes a week, it becomes second nature.

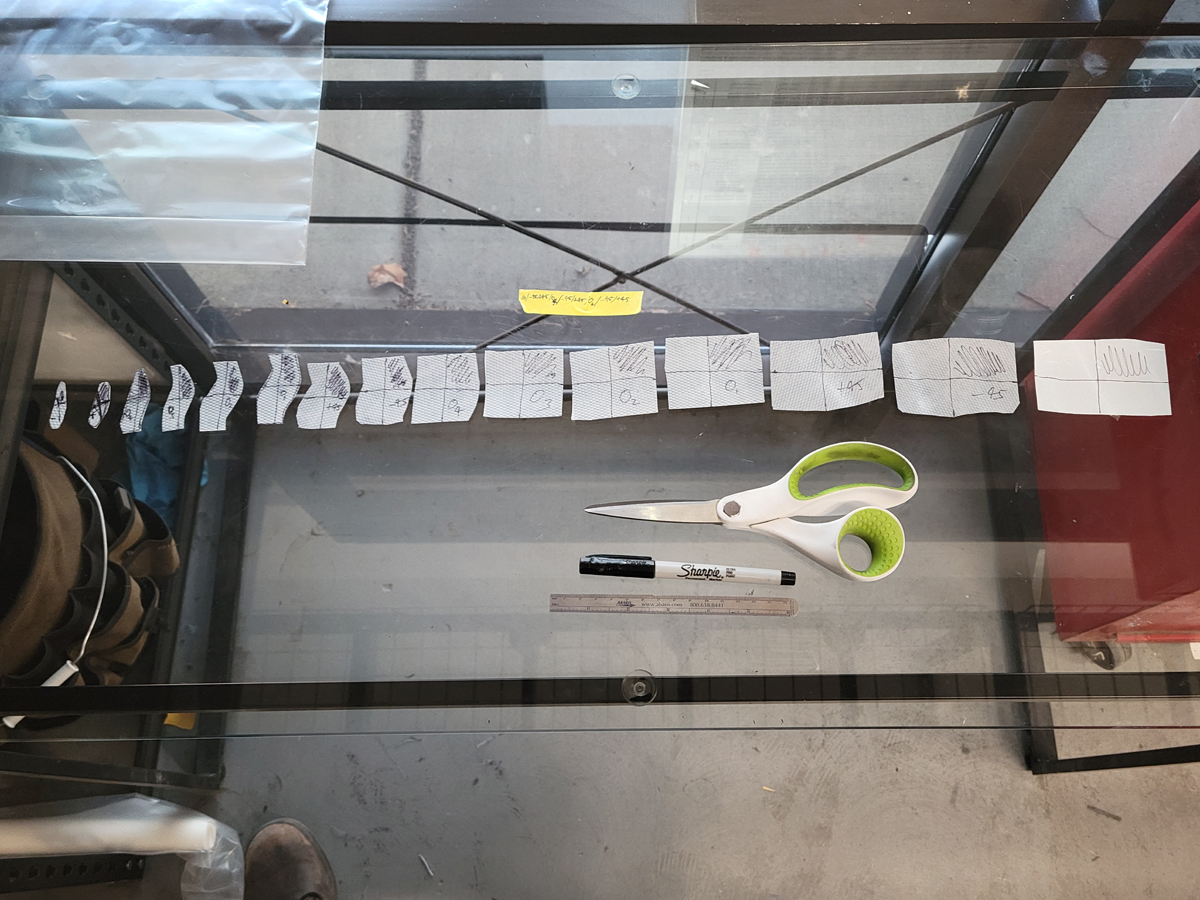

- Ply tracing and cutting: Once the layup is determined, the outline of each ply is traced and cut it out in the proper orientation. Prepreg carbon fiber with a toughened epoxy resin system is used, with the resin already mixed perfectly; no wet layups.

Each ply is inspected to determine layup order and fiber orientation.

The outline of each ply is then carefully traced and cut from pre-preg carbon fiber sheets. - Layup: Each 0.005” thick carbon ply is placed onto the bike in the correct order and orientation. 0.1” of contact is needed for each ply to the matching ply on the bike to ensure proper load transfer from the bike to the patch.

Each new ply is placed on the bike in the correct order and orientation. - Curing: The full patch gets a proprietary combination of release agents, heat conductors, and high CTE uncured rubber added for processing, and is then vacuum bagged for compaction. Then, the repair area is heated at a specific rate to a specific temperature for curing; no need to fully disassemble the bike.

After activation of the pre-preg resin, the patch is vacuum bagged for compaction …

… and the repair area is then heated to cure the carbon fiber patch. - Cure removal and finishing: If there is any doubt in the repair, the Ultrasound is brought out once more to inspect the cured repair. The repair is then sanded smooth, and finished with an automotive grade clear coat for ultimate protection. Customers can also pay for a single-color paint match.

The patch is then sanded smooth and finished with an automotive grade clear-coat for protection.

A single-color paint match is also an option.

SLS: I know that building an environmentally sustainable business is part of EBC’s core beliefs, but also that working with carbon fiber is not greenest industry one can be in. How does EBC help minimize their impact on the environment with regards to waste from the repair process and/or unrepairable frames? Is there a way to recycle carbon fiber, or to dispose of it in an environmentally sound manner?

JW: I started East Bench Composites to reduce waste in the cycling industry. The current carbon fiber industry is not environmentally sustainable at all. While carbon fiber can be downcycled into lower grade materials, such as milled fiber tire levers and 3D printing filaments, it just isn’t the same as recycling. It is extremely rough on the environment to produce carbon fiber bikes (or anything else) and they cannot be recycled, period. So, when a bike gets warrantied, it goes to the dump. With the rate the sport is growing, it is entirely unsustainable for people or manufacturers to simply throw away cracked carbon frames.

We want to give people another option. Instead of throwing out damaged frames, we are taking products that are effectively waste and repairing them correctly, therefore drastically minimizing the resources it takes to get riders back on a bike. We have dialed in our process to use minimal processing materials; for an entire repair the waste created is only about the volume of a baseball. When done right, carbon repair is a perfectly safe, sustainable option.

SLS: I understand that in addition to doing repairs on bikes belonging to individual cyclists, EBC is also acquiring broken frames, repairing them, and then reselling the frames. Can you tell us about that program? Are there any particular manufacturers that you’re working with?

JW: We are stoked to formally announce our partnership with Trips for Kids. Trips For Kids national non-profit organization works to make bicycles more accessible to kids in communities across the country. Funding this mission relies on sponsors, volunteers, and donations, including those from the bicycle shipping company BikeFlights.

Here is how it works: Occasionally, bikes – especially those that have been inadequately packed – get damaged in shipping. After a damage claim is approved and paid, damaged bikes are often donated to Trips for Kids. If these bikes are newer and have repairable carbon damage, East Bench Composites will purchase the bikes from Trips for Kids and repair them for resale. This means that a non-profit gets the income they need to help get more kids on bikes, and the frames stay out of the landfill and get a second lease on life. It’s a win-win, and we are immensely proud of this relationship.

SLS: Are these frames repainted and sold without the original manufacturer’s branding (or with EBC branding), or are they sold as a used & repaired brand-name/model?

JW: Yes, these bikes are being sold as a repaired, used frame with the company’s branding. We aren’t trying to hide the fact that this is a repaired carbon bike, because carbon is rad. We are proud of the fact that this bike was repaired correctly and can be safely ridden indefinitely.

SLS: Does EBC repair other items, such as carbon wheels, forks, or cockpit components (handlebars/stems/seatposts), or do you strictly work with frames?

JW: We have done minor repairs on forks, and wheels can often be repaired depending on where the damage is located. To repair wheels, they need to be disassembled, and the damage cannot be over a spoke hole. Unfortunately, cockpit items are usually not worth the cost of repair. The exception to this is proprietary seatposts and bars for Triathlon bikes and other aero road bikes, which we have done plenty of repairs on.

SLS: What sort of warranty do you offer on your various repair services?

JW: All of our bikes come with a 5 year fully transferable warranty on the repair area, including 1 inch in any direction. We record the serial number of every bike we repair, and the warranty applies to anyone who owns that bike. In 2 years and in the roughly 250 repairs completed, we have never had a single warranty claim.

SLS: What do you see for the future of EBC? Are there any plans to invest in tooling to build your own frames and/or components from design up?

JW: Creating new carbon fiber bikes is not something we are interested in due to the environmental cost. Our mission is rooted in reducing waste, and until carbon fiber can be properly recycled, creating more of it is a non-starter for us.

In the immediate future, we are focusing on improving our finishing and paint methods. We are extremely comfortable with the strength of our repairs and the efficiency of our process, but our paint matching is currently a “five-foot match”; meaning you can’t notice the repair outside of five feet. But we hope to improve this to the point where our repairs are not noticeable at all.

The long-term goal is to repair as many bikes as possible, so we can reduce as much waste as possible. In order to do this on an industrial scale, we have to attract OEs to start repairing warrantied frames instead of replacing them. But first, we have to get our repairs to the point where the repair looks factory fresh, which truly is an art form.

East Bench Composites is located at 2374 Harrison Blvd., in Ogden, Utah. They can be contacted through their website at https://www.eastbenchcomposites.com or by phone at 385-240-5265.